Lifting tables.

Go to the new lifting table pages, click here!

The lifting table is a very versatile lifting device. The lifting table can be used to lift different pieces/products from one level to another. Lifting tables are used throughout the industry. And at most for loads of 125 tons.

Use of the lifting table:

At its simplest, the lifting table is used so that the pieces are lifted from floor level to an ergonomic working height where the actual work is done in the correct working position. This is how it works, e.g. in the assembly industry, workshops, maintenance facilities, warehouses. This can also improve the well-being of the personnel.

The lifting table is also used at loading docks where loads can be lowered or raised to the right height so that the pieces can be moved to or from the truck. Lifting tables are also used as goods pallet lifts, which are used to move items from one floor to another.

Conditions and surface treatment:

Lift tables can be used in all conditions, indoors, under a canopy outdoors or directly outdoors. You can choose from steel, galvanized steel or stainless steel as a surface treatment

alternatives to difficult circumstances.

Special solutions

The program includes basic structures but also fully customized solutions according to the customer’s needs.

Standard structures:

1-scissors multiple scissors, consecutive multiple scissors, stacked max 125 ton max 50 ton max 50 ton

low Rst lifting tables Tilting

goods pallet jacks

Accessories:

When you request an offer from us, think about these questions in advance: Lift table questionnaire

Special lifting tables:

Send us an inquiry and we will answer soon, and tell you how we can serve you. Lifting table questions

Manufacturers’ brochures:

Lifting tables, Onderlift Lifting tables Armanni Lifting tables Angel-Mir

See the brochures above for accessories!

The selection of lifting tables includes: basic 1-scissor tables for loads up to 125 tons

2-4 scissor tables, scissors on top of each other for loads of max 50 tons

2 – 4 scissor tables, scissor in a row: for loads max 10 tons

the instructions also include high-lifting lifting tables where several Saksi work on top of each other, as well as combinations of these.

Low-level lifting tables are also available, for loads of max 2 tons

The tilting models are also included in the program:

Accessories are available for all tables.

TECHNICAL BASIC SPECIFICATION. Lifting tables and loading docks are CE-marked and manufactured in accordance with the EU Machinery Directive and Euronorm EN1570. Two maintenance supports keep the table firmly in place during maintenance and repairs. Power supply is 3 x 400V3v50Hz. The control voltage is 24V DC. The protection class of the table is IP54. Safety is increased by the safety strips, below the tabletop of the lifting table, which stop the lowering movement of the table if there is an obstacle in between. The hydraulic hoses are equipped with hose break valves to prevent uncontrolled descent. The overload protection is adjusted according to the maximum load. he hydraulic cylinders are chrome-plated and polished and tested and equipped with high-pressure seals. All lifting tables are factory tested with +30% overload. The tables are equipped with lifting eyes. The tables are also equipped with upper limit switches.

Lifting tables and loading docks are made of high-quality components, which improves reliability, durability and safety.

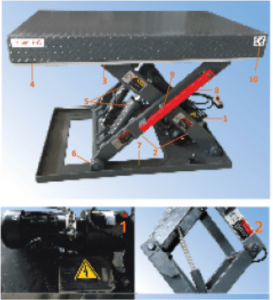

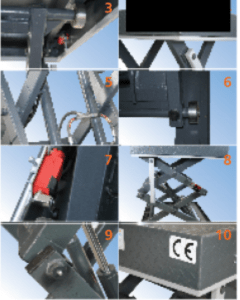

1.Kompakti hydraulinen voimayksikkö, jossa on metalliöljysäiliö

Hydraulinen on vakiona varustettu ylivuotoventtiilillä..

Imusuodatin on rakennettu säiliöön melun minimoimiseksi.

Yksikkö on IP65, moottori IP54, roiskeen kestävä.

2.Saksivarsien neliömäinen teräsrakenne antaa erinomaisen sivuttaisen

vakauden. Vahvat laakerit kaikissa liikkuvissa osissa vähentävät

laakerin kuormitusta, mikä pidentää laitteiden käyttöikää yhdessä

kaikkien kääntöpisteiden rasvanippojen ja anodisoitujen tappien kanssa.

3.Tarkasti työstetyt sakset varren kääntökeskukset ja koneistetut

profiloidut varret takaavat sujuvan suorituskyvyn ja geometrisen

liikkeen tarkkuuden.

4.Metalliprofiilinen turvakehys tarttumisriskin vähentämiseksi.

5.Sylinterit on varustettu pehmustuksella, jotta sulkeminen

ei tapahdu kolhuilta. Jokainen sylinteri on varustettu letkun

rikkoutumisventtiilillä, joka varmistaa välittömän pysähtymisen

putken tai letkun rikkoutuessa.

6.Haarukalla varustettu tela varmistaa täydellisen kuormituksen

tasapainottamisen ja eliminoi poikittaiset kuormat pidentäen siten

käyttöikää. -telat on eloksoitu.

7.Ylärajakytkin, jolla on helppo säätää iskupituutta.

8.Mekaaniset turvalukot turvallista ja vaaratonta huoltoa varten.

9.Nopeasti vaihdettavat anodisoidut nastat ja holkit helpottavat

nostotelineiden huoltoa.

10- CE-merkitty

Nostopöytäkysely: Nostopöytäkysymykset!

Nostopöytäkysely: Nostopöytäkysymykset!

Search words: Lift table, lift tables, scissor table, scissor tables, low lift tables, loading dock, loading docks high lift lift tables